Building Blocks of our Business

A Journey in Innovation,Technology and Sustainability.

Starting From conventional construction we have flown swiftly to the Future of Construction

New Age technologies explored adapted and pioneered by us on our swift journey:

1. A blue metal quarry with 4 stage processing for quality aggregates.

2. One of the first automated Manufactured Sand (Msand) plants in the State.

The exploitation and degradation of natural resources especially rivers by extraction of River sand is one of the primary ecological hazards being faced by the country. We were among the first companies to set up a state of the art Manufactured Sand plant from aggregates and shift all our consumption to this product. Msand is stronger and more economical than river sand and is a green product. We adopted a technologically superior 3 stage process and set up a full pollution treatment and waste recycling plant too.

3. Fully automated imported Block Making Lines for Hollow core blocks, construction blocks, fly ash bricks, pavers, kerb stones etc.

We went one step further and imported special production lines from South Africa and China for hollow core blocks and had them designed to our specifications to reuse the by-products generated from our MSand plant and Quarry, thus achieving Zero waste discharge. The blocks are as strong as conventional bricks and much better even in finish. Again a green product.

4. Foam concrete Plant with technical know-how from Dr.LUCA GMBH, Germany.

Continuing our journey towards Innovative Green products, we imported a complete Foam Concrete Line from Dr Luca GMBH Germany. Aerated light weight cellular concrete manufactured using foaming agents, cement, flyash or sand and nano-formers to enhance strength, has high thermal resistance and is only 1/3rd the weight of regular concrete.The concrete is formed by adding foam and injecting millions of vacuum bubbles. Neither heat nor sound can pass through vacuum so the product is light and energy efficient.

It can be used to make blocks,cast in situ walls or as thermal insulation or lightweight infill for sunken areas,rooftops etc.It is also used for decorative purposes.We have built over a Million square feet of buildings using this technology,which is very energy efficient and brings down overall cost of ownership in buildings with high energy requirement like malls,hotels,offices etc.

5. Concrete Ready Mix Plants.

6. Complete construction, surveying and earth moving equipment including – Total Stations, Excavators,Backhoes,Trucks, Lifting/ Conveying equipment,Dumpers,Cranes etc.

7. Equipment for building finish solutions including automated plastering, rendering,painting etc.

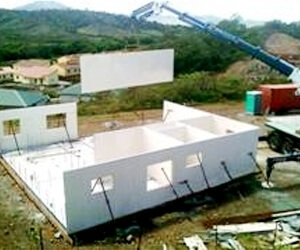

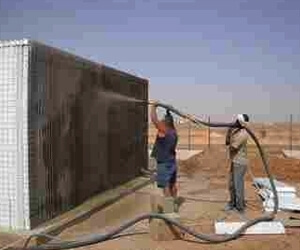

8. EPS 3D Panels

The next step in our journey was construction using 3D panels with an Expanded Polystrene core and a special steel space frame welded on .The panels are light weight and the EPS core makes them thermally and acoustically efficient.The panels are joined together and shotcreted to cover the steel frame, then plastered and finished.

A simple quick procedure resulting in a green rated building.This technology is useful for certain special applications.The overall cost makes the application field limited.

9. All Steel Buildings

We pioneered all steel construction in the country for non-industrial purposes and erected one of India’s largest All steel buildings,covering a Million sq feet.Each floor plate was close to 100,000 sq feet.The pillars and beams were erected with special steel from Arcelor Mittal UK and the floor slabs were cast with steeldecking as lost formwork. The walls were clad with Foam concrete blocks.

10. The Ultimate Destination – GFRG / BACE SWIFT BUILD

Our journey through various construction options and the close interaction we had with leading international players in the construction field brought us to what we consider as the Ultimate Destination in Green Sustainable Affordable Construction – GFRG / BACE SWIFT BUILD. We have set up the Only Plant in India to manufacture GFRG Panels. We have worked closely with the Civil and Structural Team of IIT Chennai to adapt this technology to Indian conditions and we have emerged as the lead player in this field, having executed the maximum number of projects in India, with many more in various stages of construction and planning.